J-Seal® PU1-800 (GG) is a permanently elastic, one component, gun grade polyurethane joint sealant specifically developed to be used as a multipurpose sealant in applications where a high chemical resistance to fuels, oils and hydrocarbons is required. It is also suitable for use in potable water structures. It cures under the influence of atmospheric moisture to form a low modulus sealant with excellent adhesive properties and resistance to ageing and weathering.

Certified according to:

EN 15651/1 TYPE F INT/EXT CC ; EN 15651/4 TYPE PW INT/EXT CC

Compliant to:

ISO 11600 Type F Class 25 sub-class LM ;

ASTM C920 Type S Grade NS Class 25 Use T1, M, A, O.

Potable water certified to AS/NZS4020 by The Australian Water Quality Centre (AWQC)

Note: The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

Toggle Content

Toggle Content

SURFACE PREPARATION

Joint surfaces must be dry, clean and free of all contamination. Glass, metal and other non-porous surfaces must be free of any coatings and wiped clean with solvent. Precast panels using form-release agents, other than polyethylene film, must be sand-blasted or mechanically abraded and dust free.

PRIMING

J-Seal® PU1-800 (GG) has general good adhesion properties even without the use of primer on most common building materials. However, varieties of brick, natural stone, plastics, paints, coatings and other treatments of surfaces, often present a difficult surface to which to adhere. Due to the number of unpredictable natures of these substrates, a preliminary test is recommended. Apply a coating of J-Seal® N49 Primer on the joint wall/surfaces.

APPLICATION

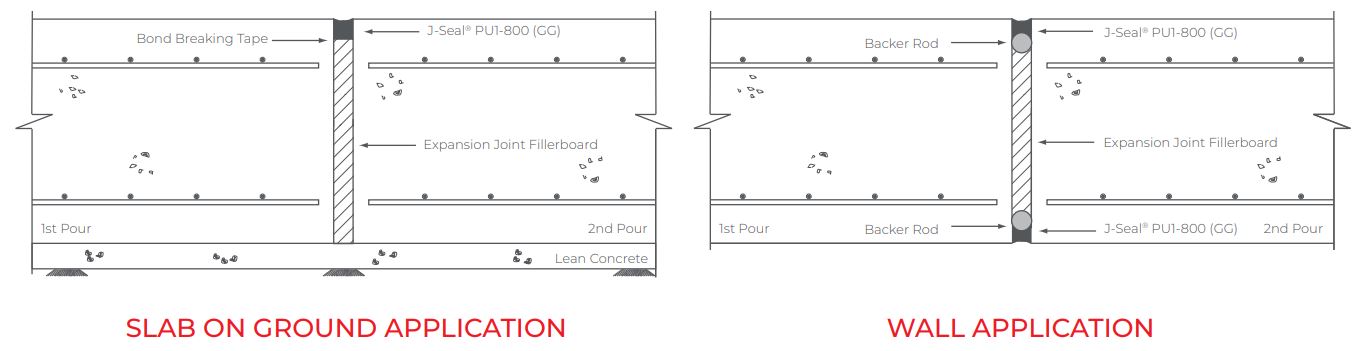

Recommended application temperatures: 5°- 35°C. For ease of use or cold weather applications, we recommend the material is stored at approximately 25°C prior to use. In order to guarantee free movement of sealant in joints, it is imperative that the sealant does not adhere to the bottom of the joint, therefore a closed-cell polyethylene bead (joint backing rod) is to be placed at the proper depth or a bond-breaker tape applied. Apply J-Seal® N49 Primer to the sides of the joint and allow to become touch dry before applying sealant. For best performance, sealant should be gunned into joint when the joint width is at mid-point of its designed expansion and contraction position. Firmly extrude sealant into the joint making sure that it is in full contact with the sides of the joint and with the backing rod or a bond-breaker tape at the bottom. Keep the nozzle inserted in the sealant and continue on with a steady flow of sealant preceding the nozzle and avoid overlapping of sealant to eliminate entrapment of air. Sealant should be tooled to a smooth finish ensuring a full contact to the sides of the joint and to the back up material, this will also contribute in breaking any air bubbles which may be formed inside the sealant. Masking tape should be used where sharp exact joint lines or exceptionally neat lines are required. Remove the tape whilst the sealant is still soft.

Note: The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

Where shown in the drawings, the joint sealant shall be J-Seal® PU1-800 (GG) polyurethane joint sealant as supplied by CJSA. The application/installation of the product must be in accordance with the manufacturer’s recommendations and J-Seal® N49 Primer must be used in conjunction with the application of the joint sealant.

For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS), which is available upon request. In confined spaces or in still air conditions, the use of a ventilation fan or suitable respirator should be used, and the advice and approval of the Site Safety Supervisor is essential.

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information provided by the manufacturer of the product and/or the Company’s current knowledge and experience in connection with the product when properly stored, handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice, the differences in materials substrates and actual site conditions are such that no warranty in respect of merchantability of or fitness for particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or from any other advise offered by the Company. The Company also has no express or implied knowledge of any particular purpose for which the product is required and any such information given will not be taken into account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from recommended guidelines in respect of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The information contained in our brochure may change at any time without notice. Any use of this product; J-Seal® PU1-800 (GG) in any application should be approved as suitable for use/application by the Design Engineer and Project Manager.

Be the first to hear about upcoming sales, special events, and DIY ideas.