CJSA TX PVC Waterstop is a specially designed profile for use in construction or expansion/isolation joints in concrete where you require a waterstop in the joint between an existing structure to a new structure.

All types of construction or expansion/isolation joints in concrete where an existing structure and new structure meet and require a waterstop.

Note: The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

COLOUR: Orange

PACKAGING: 100mm & 150mm Wide – 3m per length

ROLL WEIGHT: Dependent upon profile type

STORAGE CONDITIONS & SHELF LIFE: 5 years from the date of production if stored properly in original, unopened and undamaged sealed packaging, in dry conditions out of direct sunlight at temperatures between +10°C and +40°C

MATERIAL TYPE: Polyvinyl Chloride (PVC)

WELDING TEMPERATURES: Approximately 190°C – 200°C

SERVICE TEMPERATURE RANGE: -25°C to +70°C

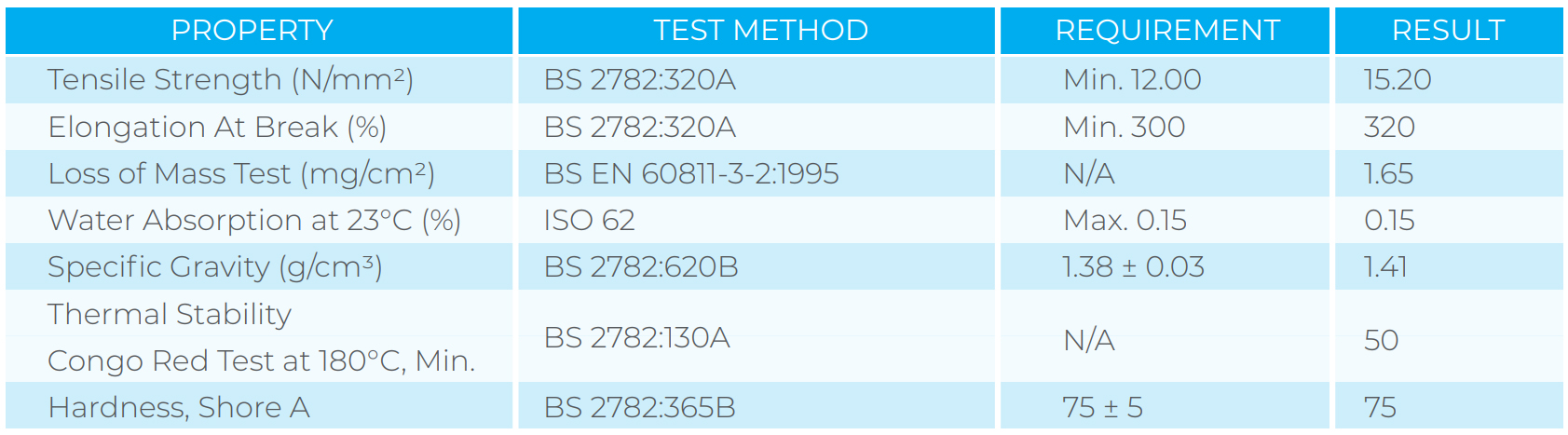

Note: Refer to CJSA’s in house Certificate of Analysis (COA) dated 13/12/2018 for test results pertaining to the above. Internal COA’s are conducted on every batch of raw material that is used in the production of TX PVC Waterstops. Independent laboratory test results are also available upon request. Project specific material properties can be custom compounded to suit. Material properties can vary between batches.

Note: TX PVC Waterstop is available in 3 metre lengths

CJSA recommends the use of its specialised welding equipment for on-site welding which consists of thermostatically-controlled Welding Irons and special Welding Jigs (each type of TX PVC Waterstop requires its own welding jig to suit the particular shape). On-site joining is a simple exercise using CJSA Heat Welding Equipment comprising of an adjustable Welding Jig and Welding Iron. The ends of the waterstop are cut square and placed into the adjustable Welding Jig, then push the ends of the waterstop against the Welding Iron and bring the two ends together until the molten ends of the PVC fuse. When ordering Welding Equipment, please advise profile number of the waterstop required. Refer to our PVC Waterstop Site Joining Guidelines for further information on the above.

Hydrostatic head pressure resistance testing has not been directly undertaken on our TX PVC Waterstop profiles.

Based on parameters documented in the Corps of Engineers document, ‘Waterstops and other Preformed Joint Materials for Civil Works Structures EM1110-2-2101, (30th September 1995)’ and installed in accordance with the installation instruction, the profile TX-150 can withstand up to 20 metre of water pressure.

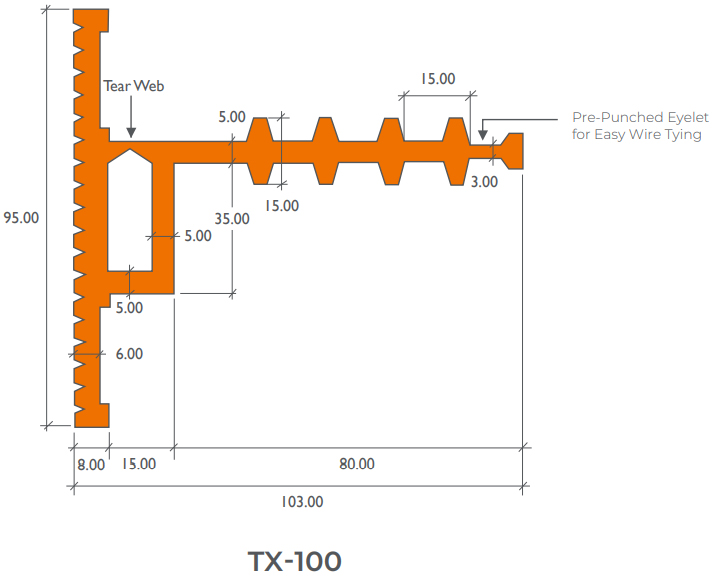

For the extension legs of the TX profiles, we have two profile lengths at 100mm (TX-100) and 150mm (TX-150) and these leg lengths of the waterstop, once cast into the new concrete section can withstand the following hydrostatic head pressure resistance:

• TX-100 @ 12 metres (1.2 Bar)

• TX-150 @ 20 metres (2.0 Bar)

Waterstop shall be TX PVC Waterstop (state profile type) as supplied by CJSA with dimensions, shape and material properties as illustrated/mentioned in their brochure. All installation and joining procedures must be according to their recommendations and requirements, and also approved by the project’s design engineer.

Joining of TX PVC Waterstops is performed by heat welding which results in the discharge of hydrogen chloride mist and vapour. In confined spaces or in still air conditions, the use of a ventilation fan or suitable respirator should be used, and the advice and approval of the site Safety Supervisor is essential. For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS) which is available upon request.

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information provided by the manufacturer of the product and/or the Company’s current knowledge and experience in connection with the product when properly stored, handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability of, or fitness for, particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or from any other advice offered by the Company.

The Company also has no express or implied knowledge of any particular purpose for which the product is required and any such information given will not be taken into account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from recommended guidelines in respect of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The information contained in our brochure may change at any time without notice. Any use of this product, TX PVC Waterstops, in any application should be approved as suitable for use/application by the Design Engineer and Project Manager.

Be the first to hear about upcoming sales, special events, and DIY ideas.