Superstop® 47B Hydrophilic Butyl Waterstop Seal is a unique sealing compound which expands in a controlled fashion when exposed to moisture, forming a compression seal in concrete joints. Superstop® 47B is ideal for use in horizontal and vertical construction joints for cast in-situ concrete structures.

Superstop® 47B is manufactured utilising a specialised mixing process which encapsulates hydrophilic materials into a Butyl base creating a controlled, moisture-activated seal. The product has the structural integrity and the long term durability features of Butyl, as well as the ability to expand to create a SELF-HEALING JOINT WATERSTOP SEAL.

Unlike many of the traditional clay-based products, Superstop® 47B being hydrophilic polymer-based, will not expand to a point that the hydration process itself leads to the possible “disintegration” of the waterstop due to its expansion control system. This is an important issue when the engineers are looking for a seal in vertical construction joints where the joint can open due to excessive shrinkage in the concrete. In-field experience has proven that products which continually expand, may lose their structural integrity and begin to wash away from the joint when subject to a constant flow of water or from high water pressure.

Superstop® 47B does not expand prematurely from the wet weather due to its unique expansion control system which also means it doesn’t expand from the water in the fresh concrete when poured against it, which helps minimize any pre-expansion if the joint becomes ponded with water. Superstop® 47B is very unique in that it can be installed by embedding it into wet concrete of the first pour as the concrete upon drying bonds very well to the Butyl Seal.

Due to its Butyl properties, it bonds to both concrete surfaces (1st and 2nd pour) creating a gasket seal first, when used in conjunction with CJ-100 Adhesive. The wet concrete from the 2nd pour bonds tenaciously to Superstop® 47B.

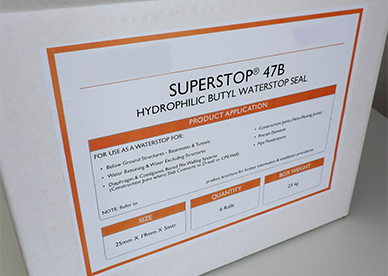

Superstop® 47B has been tested to withstand a 60 metre (6.0 Bar) head of water pressure in potable and saltwater conditions and can expand up to 180% after 30 days of continual submersion in distilled water.

Superstop® 47B complies to NSF/ANSI Standard 61 Drinking Water System Components – Health Effects, ensuring Superstop® 47B is safe for use in drinking water applications. Therefore, it is suitable to use in various potable water retaining structures like water tanks, swimming pools and reservoirs.

Note: The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

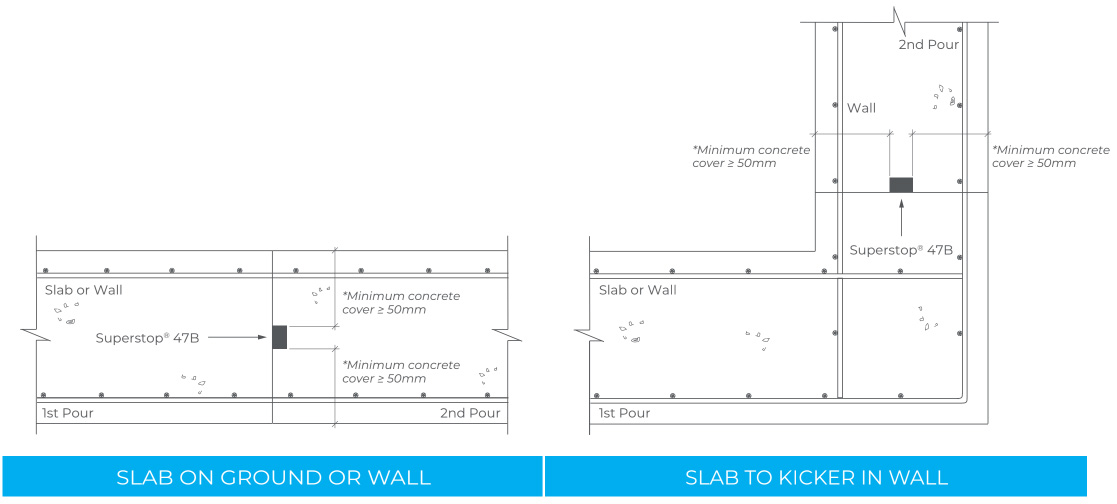

Note: Refer to above minimum concrete cover requirements. Please refer to CJSA for further

information.

Due to expansive forces, Superstop® 47B should be both detailed and installed with a minimum 50mm clear cover to the face of the concrete. Expansion rate can vary in salt and contaminated water. Increase cover when using light weight, low strength concrete. Not for use where excessive shrinkage of the concrete may occur at the joint faces. Do not stretch the Superstop® 47B during installation. Not for use in movement (expansion, isolation and contraction) joints.

1. Superstop® 47B has been tested with potable and salt water to withstand a hydrostatic head pressure resistance of 60 metres (6.0 Bar) without any water leakage or pressure drop.

2. The testing was undertaken twice, with a one month dry cycle in between the 1st and 2nd test to simulate a wet and dry cycle of the joint.

3. The above testing was conducted by an independent testing laboratory and a copy of the test report is available upon request.

Superstop® 47B requires a minimum 50mm cover of concrete from the outside edge.

STEP 1:

STEP 1:

Superstop® 47B is to be adhered to the 1st pour of concrete with CJSA CJ-100 Adhesive. A clean, dry surface free from dust, debris, etc, is required. Apply one application of adhesive onto the concrete surface and one application onto one side

of the Superstop® 47B.

STEP 2:

STEP 2:

Once both surfaces are touch dry, lay the Superstop® 47B into position and push firmly down with your fingers. If the surface is rough then you may need to use a firmer

hand pressure to make sure that the product has full contact with the surface of the concrete.

Note: The above test reports are available upon request.

Waterstops where shown on the drawings shall be Superstop® 47B controlled expansion waterstop as supplied by CJSA. The waterstop is to have a built-in expansion control system to minimise any pre-expansion prior to the second pour taking place and be able to withstand up to 60 metres (6.0 Bar) hydrostatic head pressure resistance. The waterstop is to be placed in accordance with the manufacturer’s installation guidelines, and the Design Engineer’s specification.

In confined spaces or in still air conditions, the use of a ventilation fan or suitable respirator should be used, and the advice and approval of the Site Safety Supervisor is essential. For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS), which is available upon request.

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information provided by the manufacturer of the product and/or the Company’s current knowledge and experience in connection with the product when properly stored, handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability of, or fitness for, particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or from any other advice offered by the Company.

The Company also has no express or implied knowledge of any particular purpose for which the product is required and any such information given will not be taken into account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from recommended guidelines in respect of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The information contained in our brochure may change at any time without notice. Any use of this product, Superstop® 47B, in any application should be approved as suitable for use/application by the Design Engineer and Project Manager.

Be the first to hear about upcoming sales, special events, and DIY ideas.